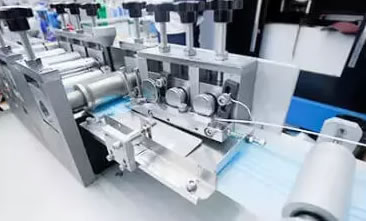

Disposable Mask Production Machine

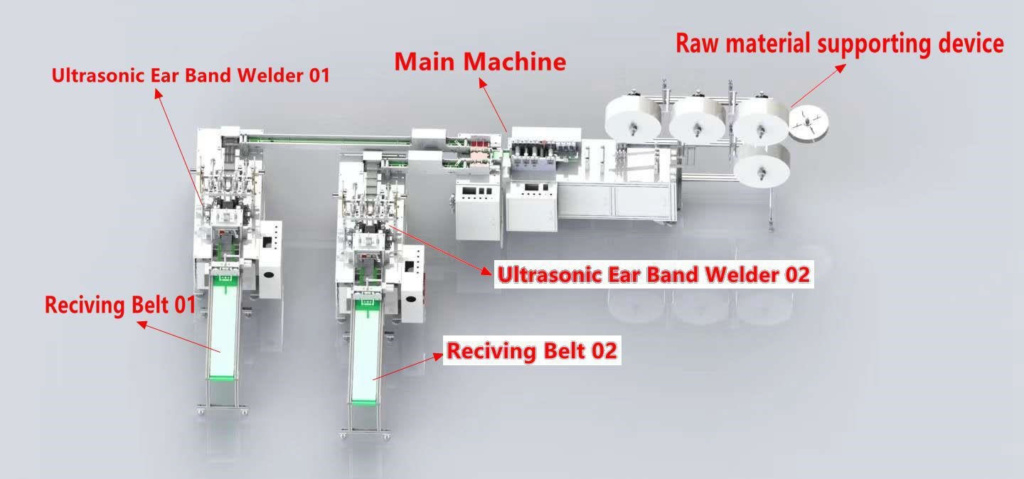

The machine is used to fully automated to produce disposal masks. The main advantage of the machine is high speed. The speed of the machine can be up to 130pcs per minute. The main production process flow is coil material feeding, nose bridge tendon feeding, folding, and pressing, mask cutting and forming, ear band feeding and ultrasonic welding, and finished product unloading. Automatically completes production from raw materials to finished masks. The produced masks are comfortable to wear, no pressure, good filtering effect of the masks, fit the human face, and can be used in medical, electronics, mining, construction, and other industries.

Mask Making Machine Parameters

| Parameter | Standard Specifications Mask Making Machine |

| Power supply | 220V Single Phase |

| Control System | Fatek PLC, Taiwan |

| Sensor | Yes |

| Pneumatic | Japan SMC, Taiwan AirTAC |

| Operation screen | Touch screen |

| Lead screw | Taiwan Hiwin |

| Equipment power | 13KW |

| Equipment weight | ca.1000kg |

| Number of applicable layers | 2-4 layer |

| Control system power | 1 Phase 220V 50/60HZ |

| Air Pressure | 0.6Mpa, 300L |

| Applicable materials | PP, non-woven fabric, synthetic fiber |

| Processing methods | Ultrasonic welding |

| Finished product specifications | 175*95mm(or custom made size) |

| Transmission | Gear |

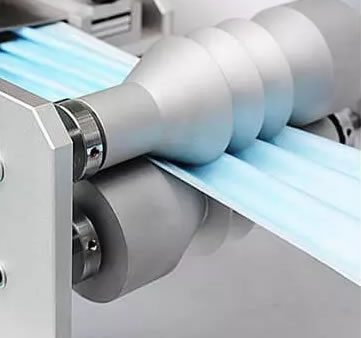

- Three layers of fabric are automatically aligned and feed, and welding system use ultrasonic waves are continuously pressed.

- The production line adopts the structure of 2 lines, with high production efficiency

- Nose clips and ear loop are automatically cut and welded by ultrasound

- Automatic counting and palletizing after welding earbands

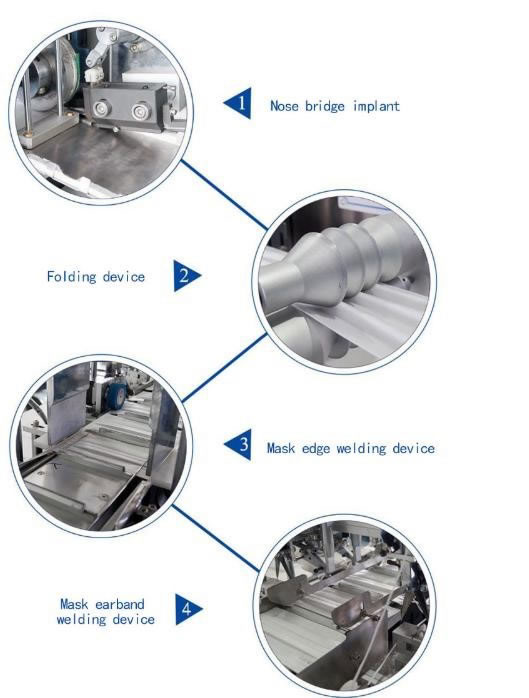

Mask Making Machine Detail Show

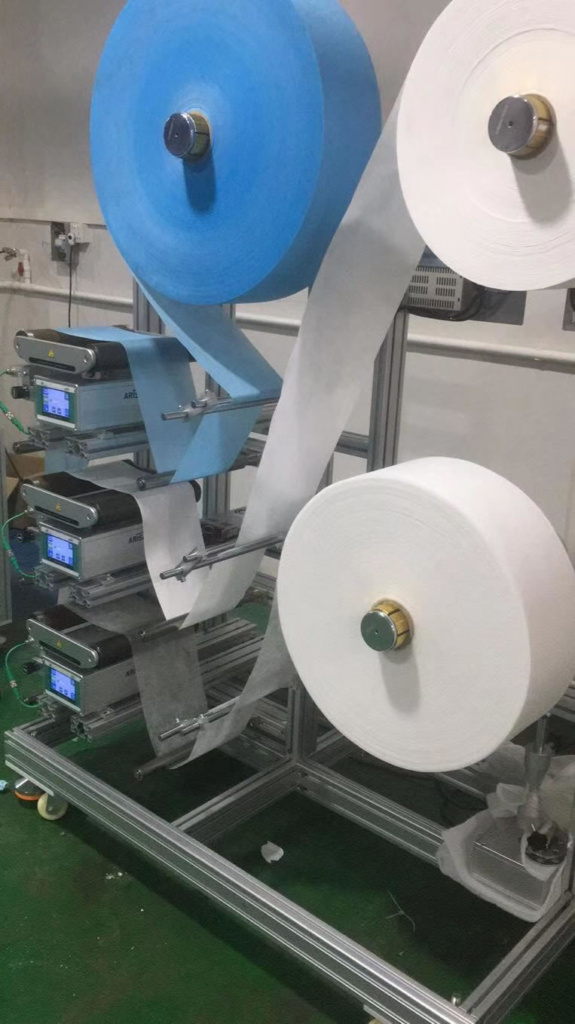

Applicable material specification:

| Item | Roll Quantity | Recommend Width (mm) | Width Range (mm) | Max. Roll Outer Diameter (mm) | Roll Inner Diameter (mm) | Weight kg |

| Out layer Non-woven Fabric | 1 | 175 | 170~200 | Φ600 | Φ60-Φ80 | max 15 |

| Inner layer Non-woven Fabric | 1 | 165 | 170~200 | Φ600 | Φ60-Φ80 | max 15 |

| Meltblown fabric | 175 | 170~200 | Φ600 | Φ60-Φ80 | max 15 | |

| Nose clip | 3 | 3~6 | Φ400 | Φ100 | max 25 | |

| Earloop | 3 | 3~6 |

Production Specification:

Raw material support

We can supply fabrics: Melt blown PFE99+, Non-Woven, Nose Wire and Ear Rope

Gear transmission

Wrinkle shapping part

Nose bridge cutting and folding function

Mask shaping and ultrasonic welding part | Mask separating device

Ear looping cutting, welding machine and Stacking Unit

Option: fabric correction device